Intelligent quantitative loading of bulk materials, laser radar ensures stable and efficient loading!

2023-12-13 16:42:58

Sand and gravel aggregates are the most basic and largest amount of basic raw materials in engineering construction. With the large-scale development of the sand and gravel industry, the loading and shipping process has become increasingly important. Especially during peak production and sales seasons, fast loading and shipping can help businesses increase profits. However, traditional manual operations are time-consuming and laborious, difficult to manage, and prone to errors. With the demand for automation, digitization, informatization, and intelligence in the production and processing of traditional sand and gravel aggregate industry, the sand and gravel aggregate industry is accelerating its development towards green, safe, intelligent, and efficient directions.

Nowadays, various advanced intelligent quantitative loading systems can achieve precise quantification, automatic feeding, vehicle guidance, and measurement in various stages such as bulk material loading, factory delivery, settlement, and statistics, meeting the requirements of automation, trade convenience, and full process informatization and intelligence for on-site quantitative loading.

High precision sensors and their accessories can ensure the stable operation and precise control of the loading system.

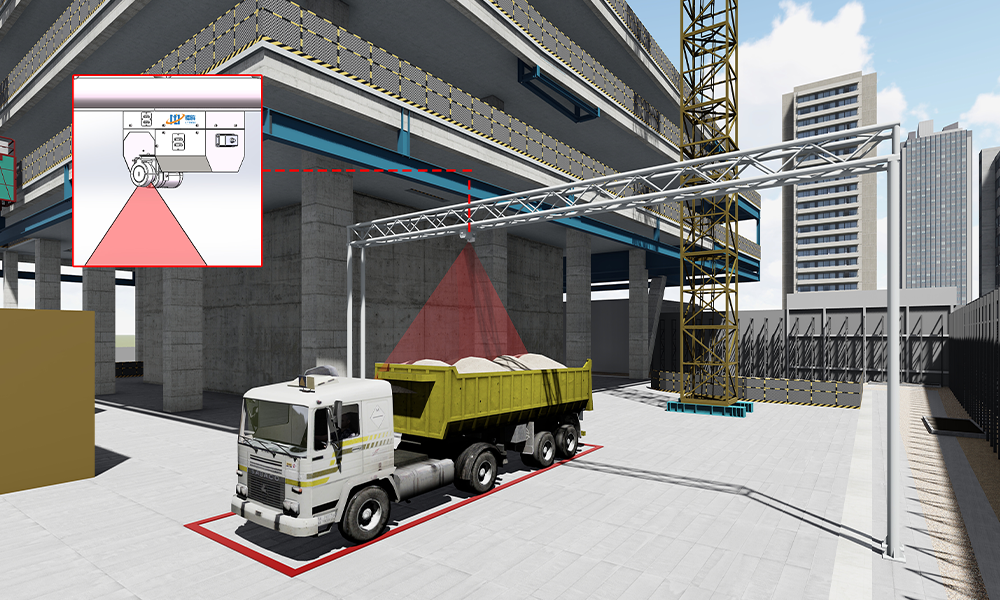

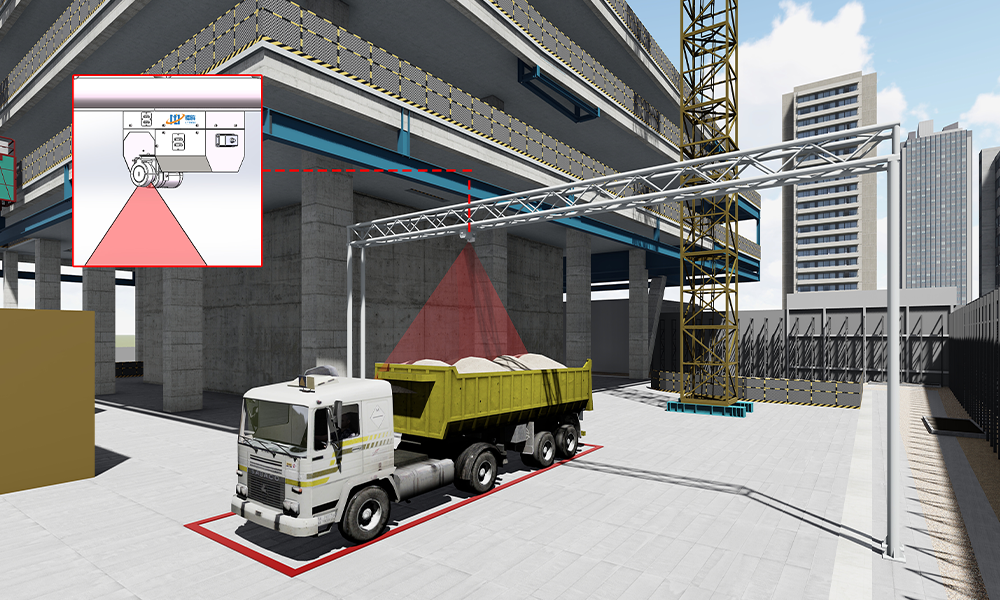

The H13 3D contour scanning LiDAR of LEIMOU can scan a wide field of view covering 180 ° * 160 ° (adjustable) in real-time through the combination of 2D LiDAR and servo motor. It can detect and scan vehicles in real time, obtain the position of the vehicle bucket through mature vehicle contour detection algorithms, and output signals to guide the system to move the vehicle forward or backward.

The dense point cloud data and volume algorithm can output characteristic information such as height, volume, and detection time of bulk cargo, accurately control the loading amount of materials, and avoid the need for repeated unloading or loading of vehicles due to excessive or insufficient loading of materials, achieving continuous, automatic, and quantitative fast loading.

Nowadays, various advanced intelligent quantitative loading systems can achieve precise quantification, automatic feeding, vehicle guidance, and measurement in various stages such as bulk material loading, factory delivery, settlement, and statistics, meeting the requirements of automation, trade convenience, and full process informatization and intelligence for on-site quantitative loading.

High precision sensors and their accessories can ensure the stable operation and precise control of the loading system.

The H13 3D contour scanning LiDAR of LEIMOU can scan a wide field of view covering 180 ° * 160 ° (adjustable) in real-time through the combination of 2D LiDAR and servo motor. It can detect and scan vehicles in real time, obtain the position of the vehicle bucket through mature vehicle contour detection algorithms, and output signals to guide the system to move the vehicle forward or backward.

The dense point cloud data and volume algorithm can output characteristic information such as height, volume, and detection time of bulk cargo, accurately control the loading amount of materials, and avoid the need for repeated unloading or loading of vehicles due to excessive or insufficient loading of materials, achieving continuous, automatic, and quantitative fast loading.

A mature automated bulk material loading system can help enterprises manage over limit and overloaded transportation from the source, and effectively prevent cheating and poor management in the production and sales process, greatly reducing labor costs and improving overall efficiency.