Application Case | LiDAR Boosts the Digitization, Informatization, and Intelligence of Automatic Loading Management.

2024-03-22 10:37:02

Background:

With the continuous advancement of industrial automation technology, software engineering also needs to keep pace with the times, discarding outdated thinking and standards to adapt to the changes of the new era. With strong support from national policies, key technologies and core technologies of automatic loading are continuously making important progress, promoting the rapid development of loading management towards digitization, informatization, and intelligence.

In order to address efficiency, safety, and information management issues, the automatic loading system introduces the "LiDAR solution," enabling intelligent recognition of vehicle position, status, loading material status, and other on-site environmental factors.

Positioning:

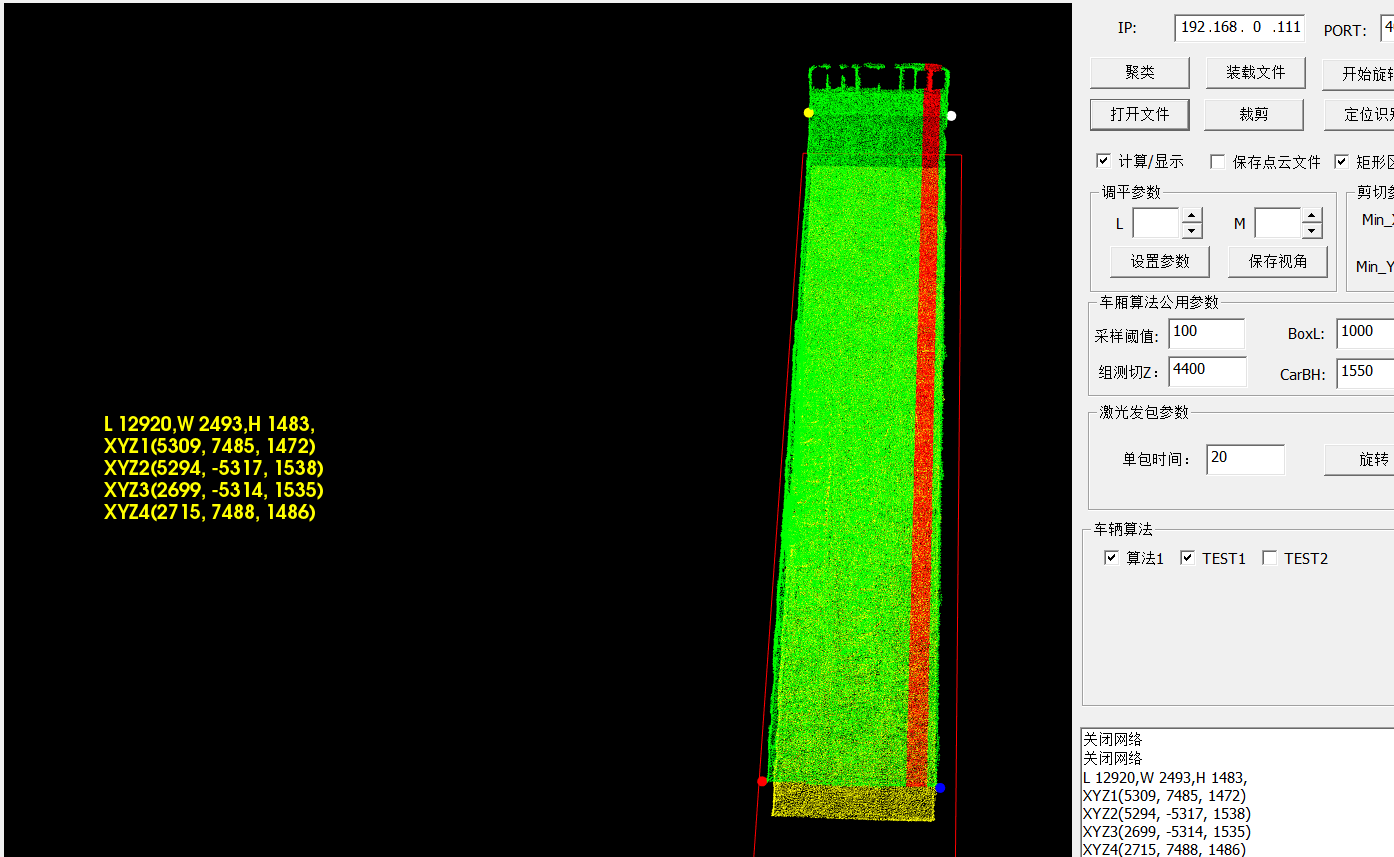

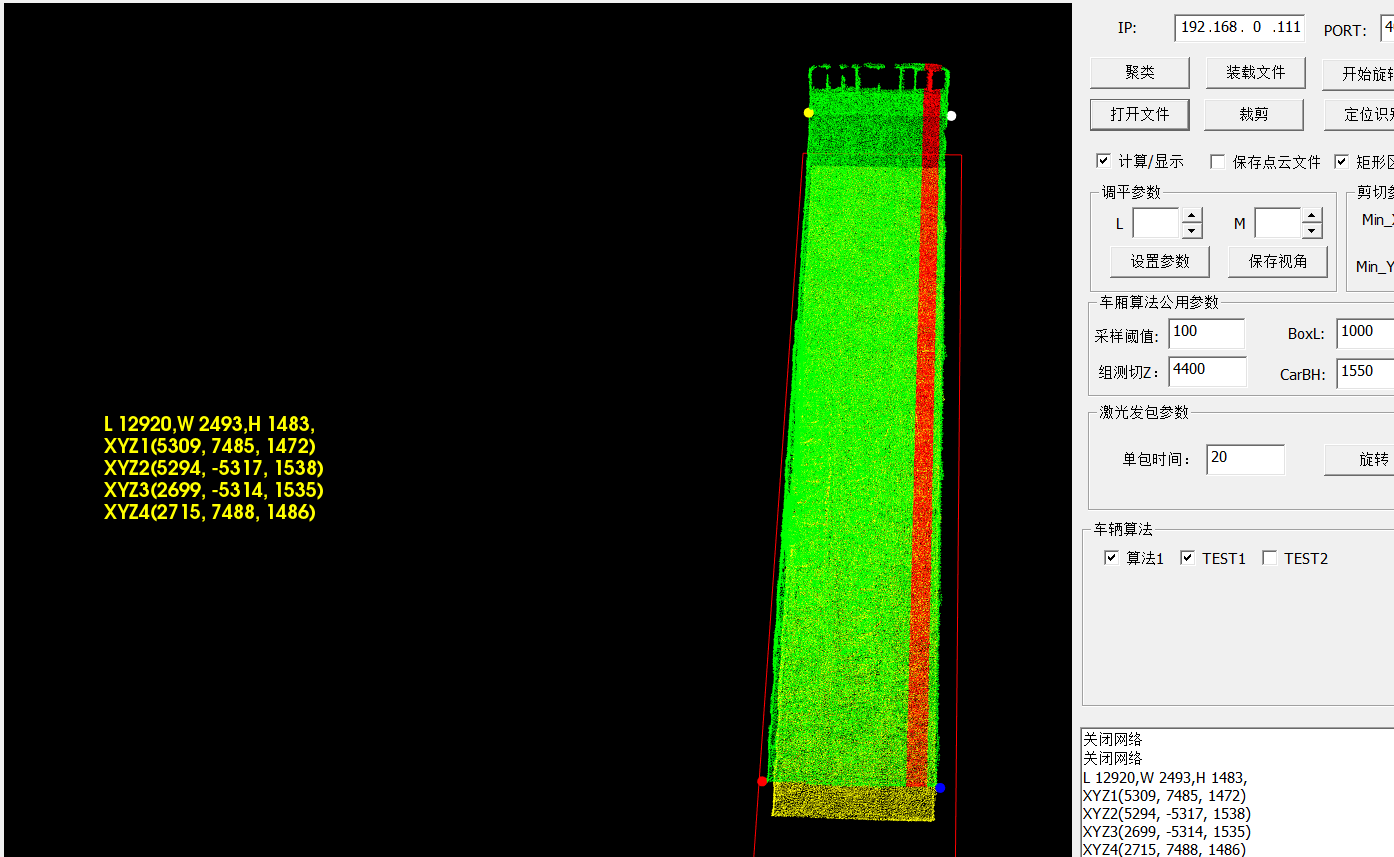

LiDAR can scan in real-time to obtain data, calculate the current position and shape of the vehicle. The system can accurately determine the vehicle's position based on the vehicle's motion trajectory and information about the surrounding environment, ensuring the accuracy of the loading operation.

Unloading:

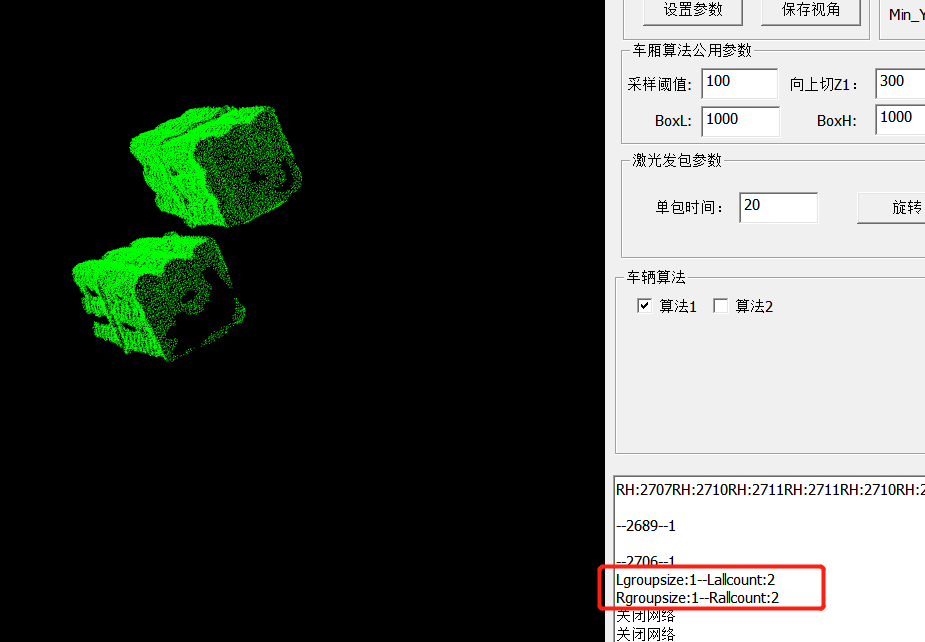

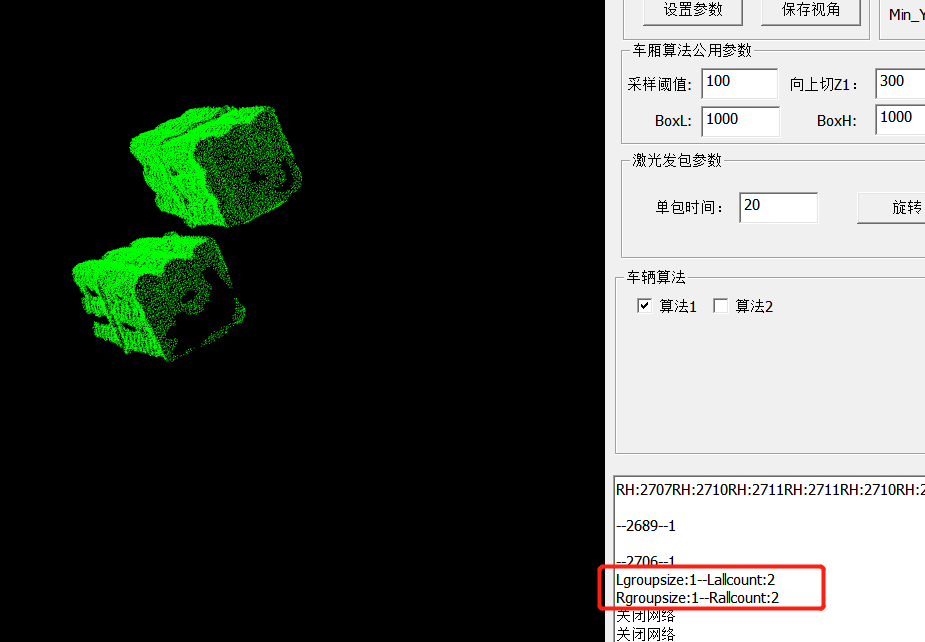

LiDAR can monitor the unloading area in real time, identifying the position, shape, and size of target objects. By detecting the target objects, the system can determine how to accurately perform the unloading operation.

Volume Measurement:

Through scans from multiple angles and positions, LiDAR can obtain three-dimensional spatial information of target objects, including dimension data such as length, width, and height. Based on these measurement data, a quantitative loading system can accurately calculate the volume of the target object.

Material Recognition:

As a manufacturer of industrial-grade photoelectric sensors, Intelly has customized and developed the Raythink ILS-H13 3D contour scanning LiDAR specifically for automatic loading systems. This LiDAR provides reliable technical support for volume measurement, positioning, unloading, etc., in quantitative loading systems through precise distance measurement and dimension capture. Its high-precision measurement capability and fast feedback speed enable the system to monitor and control the loading process in real-time, ensuring the accuracy and efficiency of loading operations, and improving the automation level of the loading system.

With the continuous advancement of industrial automation technology, software engineering also needs to keep pace with the times, discarding outdated thinking and standards to adapt to the changes of the new era. With strong support from national policies, key technologies and core technologies of automatic loading are continuously making important progress, promoting the rapid development of loading management towards digitization, informatization, and intelligence.

In order to address efficiency, safety, and information management issues, the automatic loading system introduces the "LiDAR solution," enabling intelligent recognition of vehicle position, status, loading material status, and other on-site environmental factors.

Positioning:

LiDAR can scan in real-time to obtain data, calculate the current position and shape of the vehicle. The system can accurately determine the vehicle's position based on the vehicle's motion trajectory and information about the surrounding environment, ensuring the accuracy of the loading operation.

Unloading:

LiDAR can monitor the unloading area in real time, identifying the position, shape, and size of target objects. By detecting the target objects, the system can determine how to accurately perform the unloading operation.

Volume Measurement:

Through scans from multiple angles and positions, LiDAR can obtain three-dimensional spatial information of target objects, including dimension data such as length, width, and height. Based on these measurement data, a quantitative loading system can accurately calculate the volume of the target object.

Material Recognition:

As a manufacturer of industrial-grade photoelectric sensors, Intelly has customized and developed the Raythink ILS-H13 3D contour scanning LiDAR specifically for automatic loading systems. This LiDAR provides reliable technical support for volume measurement, positioning, unloading, etc., in quantitative loading systems through precise distance measurement and dimension capture. Its high-precision measurement capability and fast feedback speed enable the system to monitor and control the loading process in real-time, ensuring the accuracy and efficiency of loading operations, and improving the automation level of the loading system.