The gantry laser vehicle detector is a laser application product developed by Yintaili Technology in the context of intelligent transportation. Through laser measurement technology, it dynamically scans vehicles passing through at high speed, instantly obtaining the external characteristics of the vehicle. By utilizing the characteristics of laser high-speed scanning, it can accurately detect the following or parallel status of vehicles, ensuring the accuracy of vehicle traffic statistics, without too many or missing vehicles.

The H1X 3D contour scanning LiDAR is based on the combination of a 2D LiDAR and a servo motor, which can scan a wide field of view covering 180 ° * 160 ° (adjustable). With professional laser point cloud computing software in the background, it can directly output external dimensions, volume, feature coordinates, 3D point cloud images, and other information.

And the combination of the two has achieved a complete application scenario of automatic loading in coal mines!

Application Cases of Coal Mine Plants

This solution has been delivered to multiple coal mines by Taili, achieving a complete version of automatic loading and assisting in the implementation of an unmanned loading system for smart mines.

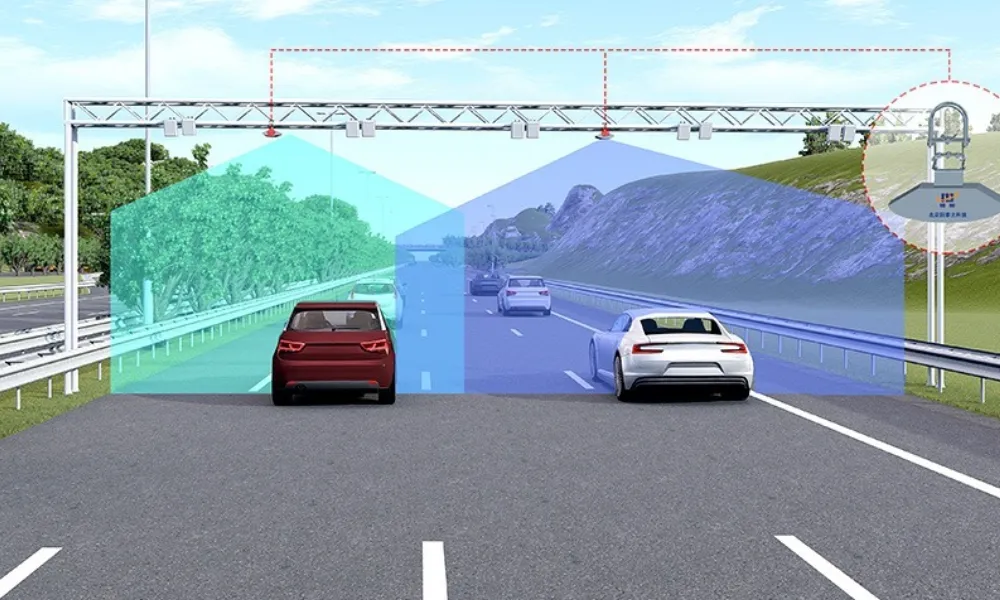

Before the vehicle enters the loading channel, a set of gantry laser vehicle detectors are deployed to scan the vehicles passing below. When the vehicle completely passes through the radar scanning area, a 3D model of the passing vehicle is obtained. After system analysis, the front and rear dimensions of the vehicle are determined, and the front and rear carriages are divided, with a focus on analyzing the length, width, and height of the carriages. The loading model is automatically calculated, providing a basis for directing the driver and controlling the chute during subsequent loading under the warehouse.

Afterwards, the vehicle enters the silo loading process, where the H1X 3D contour scanning LiDAR performs carriage positioning and material pile detection, and cooperates with the system to achieve automatic loading! During the loading process, H1X can scan the shape of the coal pile inside the carriage in real time, and intelligent algorithms calculate the coal flow information inside the carriage. When the height of the coal pile in the carriage reaches the set upper limit, the LiDAR provides a signal, and the system closes the feeding gate. Combined with voice, screen, and indicator lights, it guides the driver to move the vehicle. Ensure that the height of the coal pile inside the carriage is stable, capable of loading sufficient mass without scattering coal.

In the future, Taili Technology will continue to conduct research and development innovation, launch more LiDAR application solutions, and provide more intelligent and efficient solutions for smart factories.