Traditional forklifts have played a significant role in material handling, but they still require manual operation, which poses issues in terms of labor costs, operational efficiency, and safety. With the continuous rise in labor costs, enterprises are seeking ways to reduce costs while also facing an increasingly urgent need to improve production efficiency and reduce safety accidents.

Against this backdrop, unmanned forklifts have emerged as a solution. By integrating forklift technology with AGV (Automated Guided Vehicle) technology, and leveraging software systems, navigation, scheduling, perception, and communication modules, these unmanned forklifts can achieve autonomous driving and material handling. Not only do they fulfill the lifting and stacking needs of businesses, but they also adapt to the overall intelligent upgrading of enterprises, seamlessly interfacing with upper-level management systems and other automated equipment.

Application Challenge: Obstacle Avoidance in Complex Environments

Unmanned forklifts operate in various environments, including indoor warehouses, outdoor factories, docks, and more. These environments may present a range of obstacles, such as shelves, equipment, and varying layouts and lighting conditions. Additionally, there may be dynamic obstacles like walking personnel or moving vehicles. The positions and trajectories of these obstacles change in real-time, necessitating rapid response and flexible handling capabilities in unmanned forklifts. Given the complexity of the environment and the need for prolonged operation, a low-power, reliable, and safe solution is required to meet the obstacle avoidance needs.

Solution

The Leimou T52 three-dimensional depth imaging lidar is undoubtedly an ideal choice for meeting the fork tip positioning and obstacle avoidance needs of unmanned forklifts. This high-performance solid-state lidar provides exceptional three-dimensional imaging and depth perception for fork tip obstacle avoidance. Its features, including high precision, adaptive automatic exposure, small size, low power consumption, and high-resolution output, contribute to enhancing operational safety and efficiency, ensuring smooth operation and precise fork tip obstacle avoidance, making forklift operations smarter, safer, and more reliable.

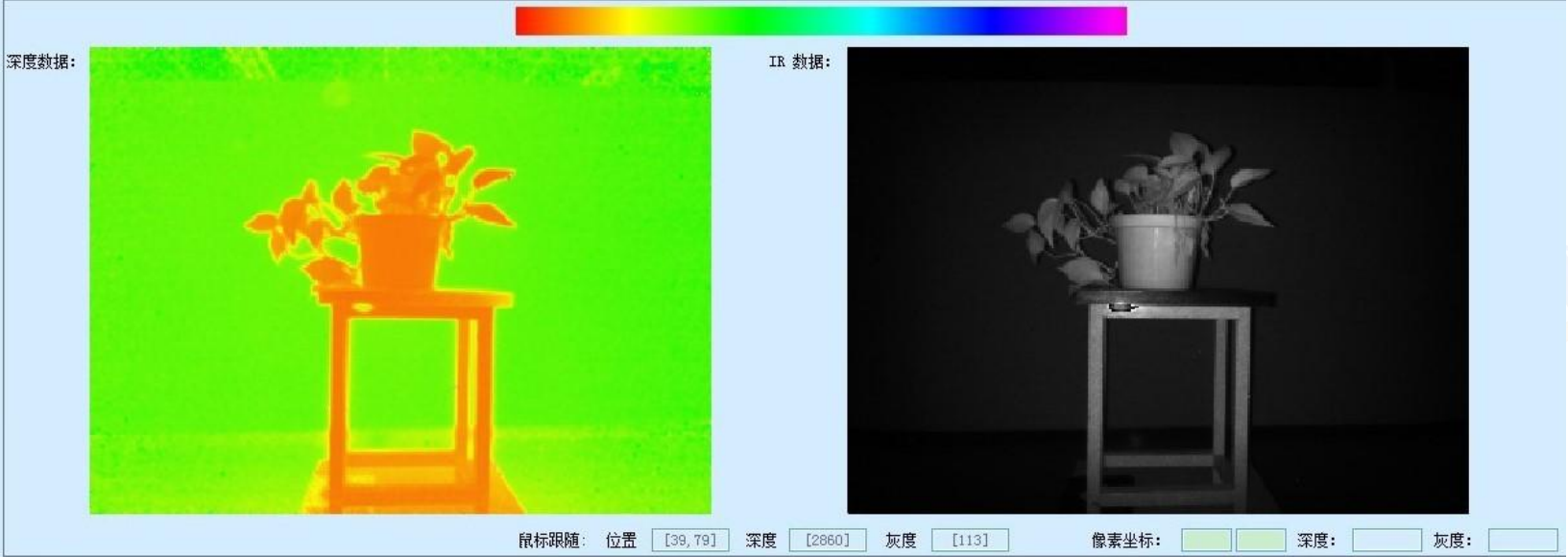

High-Precision Depth Imaging

High-precision depth imaging is crucial for the precision of fork tip obstacle avoidance, aiding unmanned forklifts in avoiding collisions and improving operational safety in confined spaces. The T52 is capable of outputting depth images and infrared point cloud data at 640x240 resolution, providing clearer environmental perception for fork tip obstacle avoidance and supporting higher-level safety operations.

Compact Size

The T52 boasts a compact size, suitable for integration into the fork tip area without occupying too much space.

T52 Three-Dimensional Depth Imaging Lidar Features

Exceptional three-dimensional image formation and depth perception capabilities

Adaptive automatic exposure

Low power consumption for prolonged operation

Compact size for direct integration into the fork tip area

IP65 protection rating

Field of view range of 120°×55°

Accuracy of ±3cm/p>

contact our customer service